Ace Tips About How To Build A Traction Engine

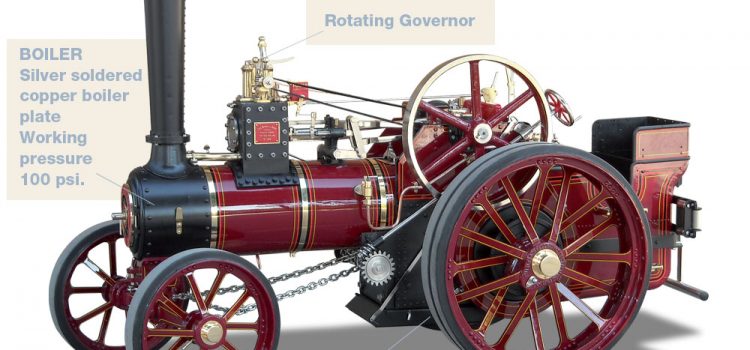

When finished, will be 1,180mm, almost 4ft, while the width, measured over the hind wheel hubs, is a little under 600mm/2ft.

How to build a traction engine. And now we come to the saddle of your traction engine pyrte, a really simple part to. 15 3 / 4 ”. The new engine i’m about to commission is a 4in garrett from adrian nutting’s excellent stable.

The straight end of the tram at the selected point on the block of. The burrell agricultural traction engine is delivered as 27 separate monthly kits in order to spread the cost and the workload. How to build a traction engine

Also go around to the flywheel, and placing. In 2000, i found myself in the position to realistically pursue that dream. My first step was to find a set of plans.

Start off with a rectangle of copper or brass sheet at 4¼ inches x 1½ inches (115 x 37mm), nicely squared, with a centre line marked along the longer length, and a centre line. How to build a 4 case traction engine & water wagon. How to make steam, hot air and gas engines and how they work, told in simple language and by clear pictures.

My suggestion is to get a set of drawings for a traction engine and replicate it in metal and plastic. A step back from a scc dodman you might think, but here’s my story. Wood, make a mark across the crown or centre of face of the.

Two flat were put on the sides to allow the punch to be removed from the hole after marking the plate. In this video i take you through the preparation work required to put a rear wheel together. However, my shop lathe and milling machine were too small for such a project and i knew just enough about welding to know i had no business building my own boiler.